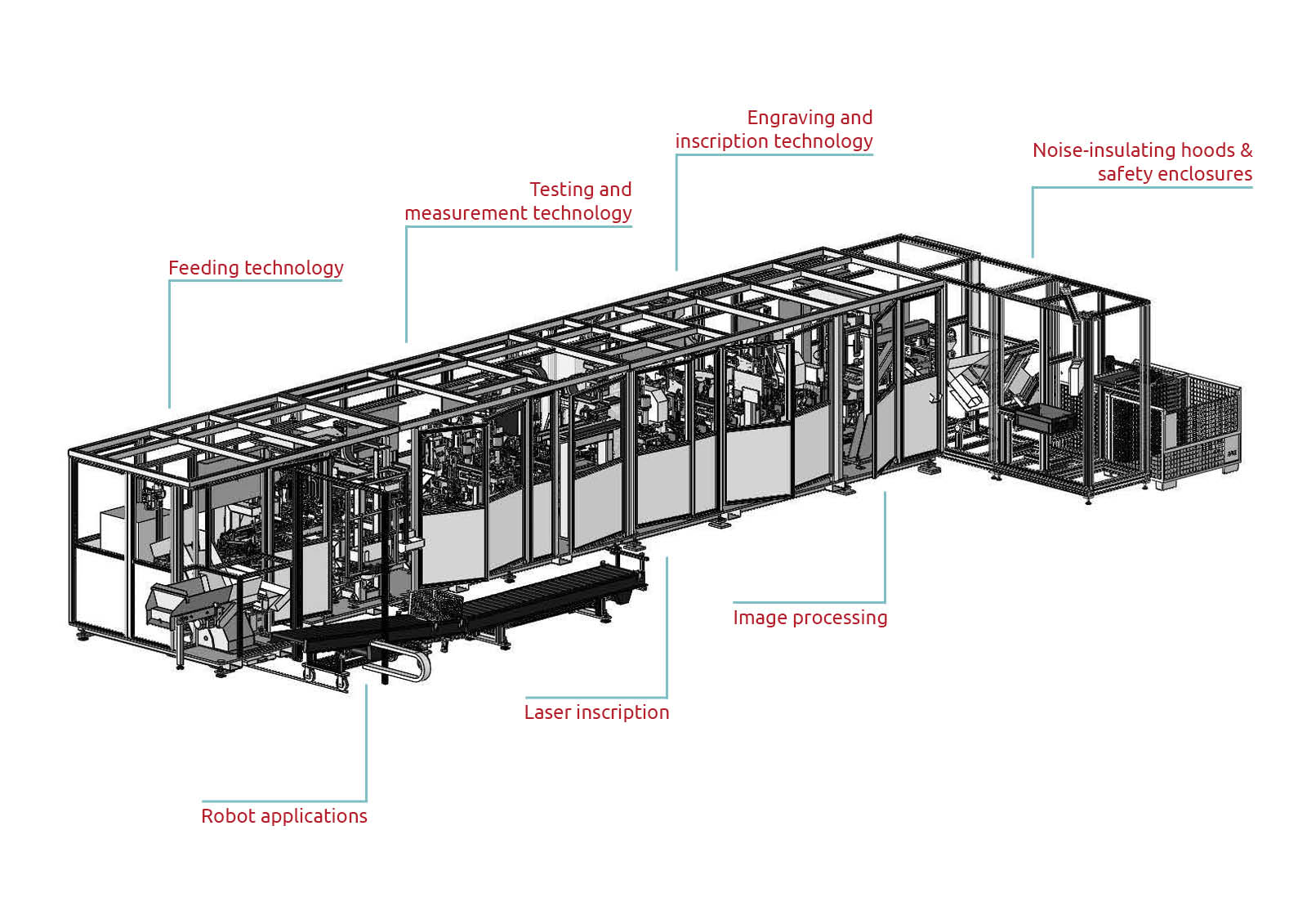

Feeding technology | Integrated feeding solutions | Interlinking and assembly automation

Integrated feeding solutions

The main function of our feeding solutions is to separate bulk material parts and transfer them in the correct position to downstream production steps. A great option is to integrate downstream production steps such as printing, laser inscription, inspection and robot handling. We are a systems provider and offer our customers integrated, turnkey feeding solutions with functional and control integration.

Overview of integrated components

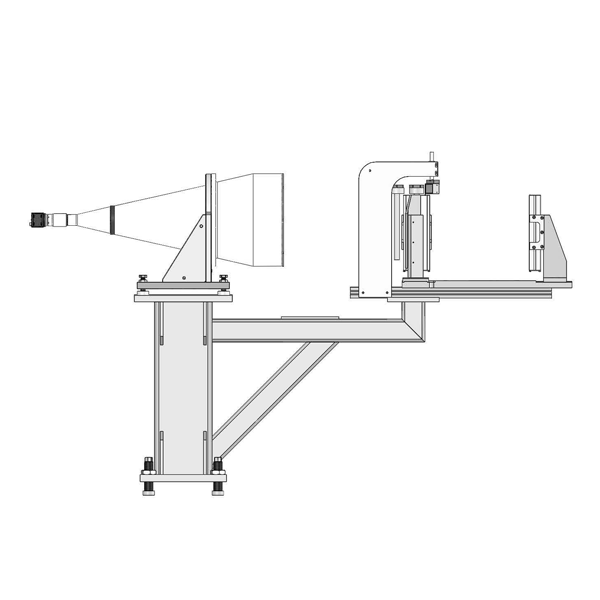

Image processing

Information

Precise length and quantity detection is key to the feeding process. It is ensure with integrated image processing and camera technology. That technology can also be used for quality control and the detection of missing parts.

Example of use

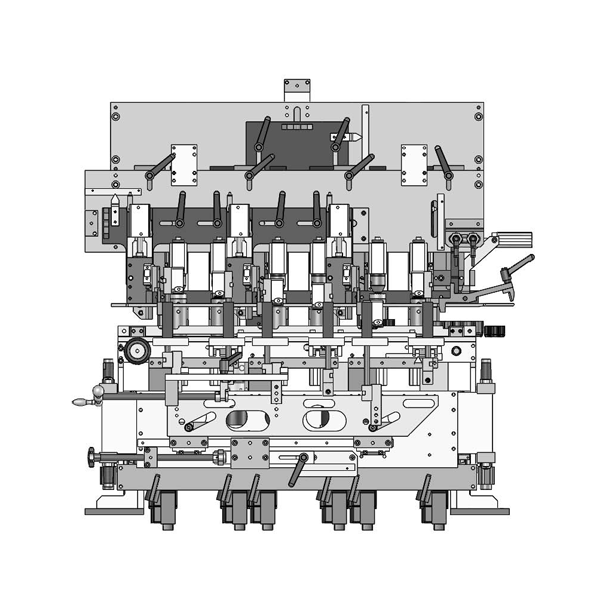

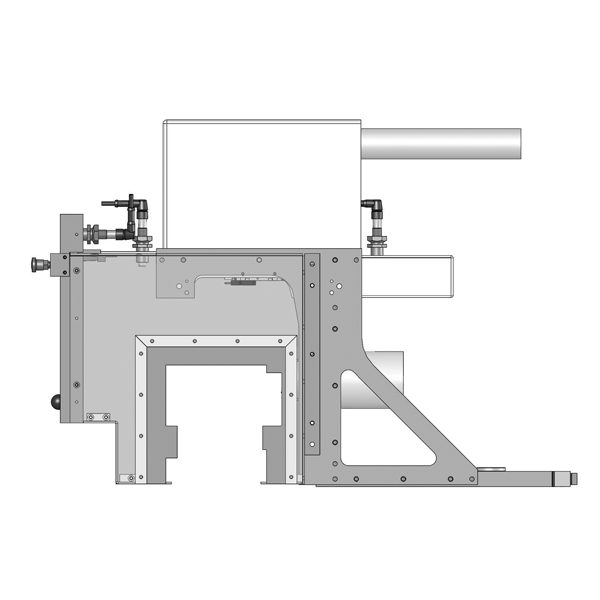

Testing and measurement technology

Information

Often, integrated quality control is required right from the feeding process to identify NIO parts and reject them if necessary. We can integrate this process into your feeding system to achieve accurate inspection results and measurements from the outset.

Example of use

Engraving and inscription technology

Information

With engraving and inscription technology, we enable our customers to engrave or label parts during the feed process. Parts are carefully adjusted and separated to ensure the exact position of the inscription.

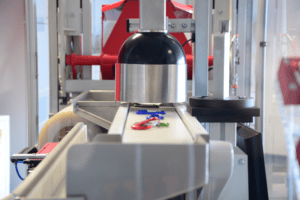

Example of use

Laser inscription

Information

We offer our customers the option of inscribing parts using laser technology during the feed process. The parts are carefully adjusted and separated to ensure the exact position of the inscription. We create permanent, waterproof and smudge-proof inscriptions for parts using the latest laser inscription systems / technology.

Example of use

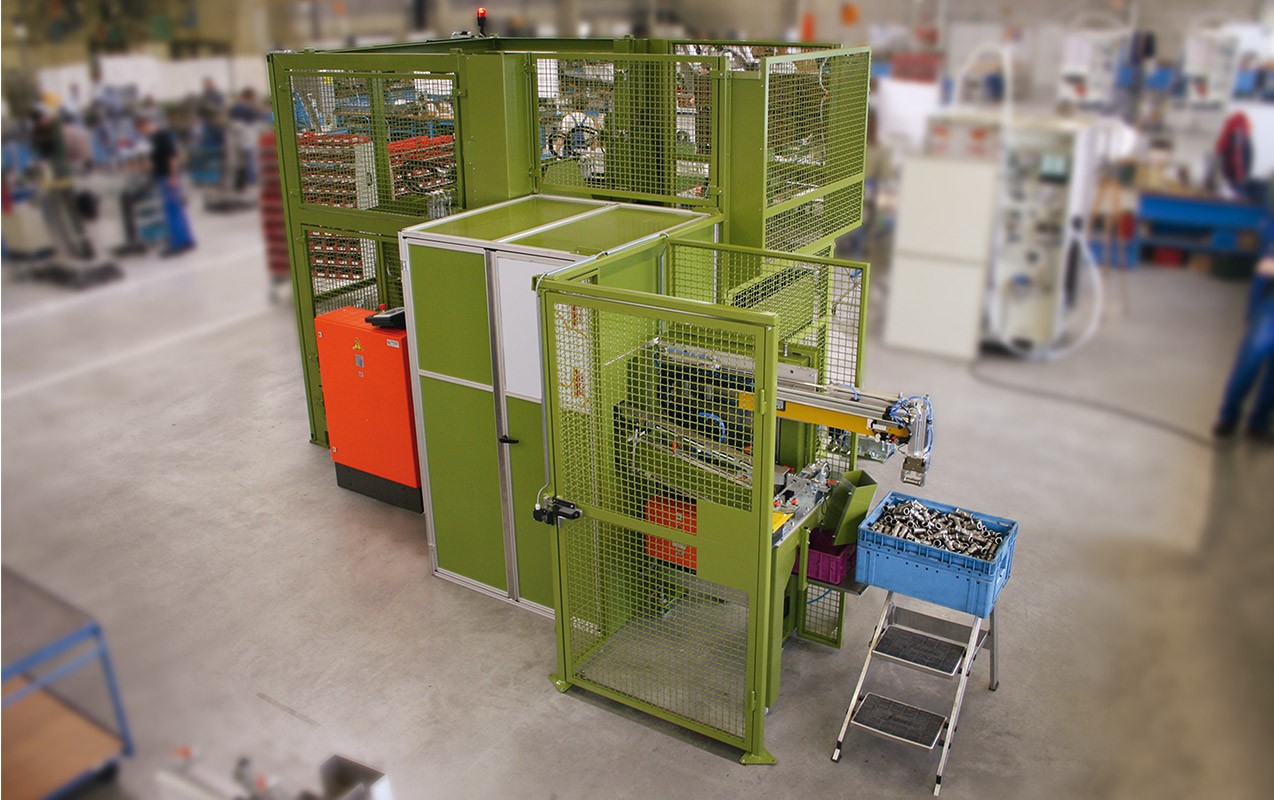

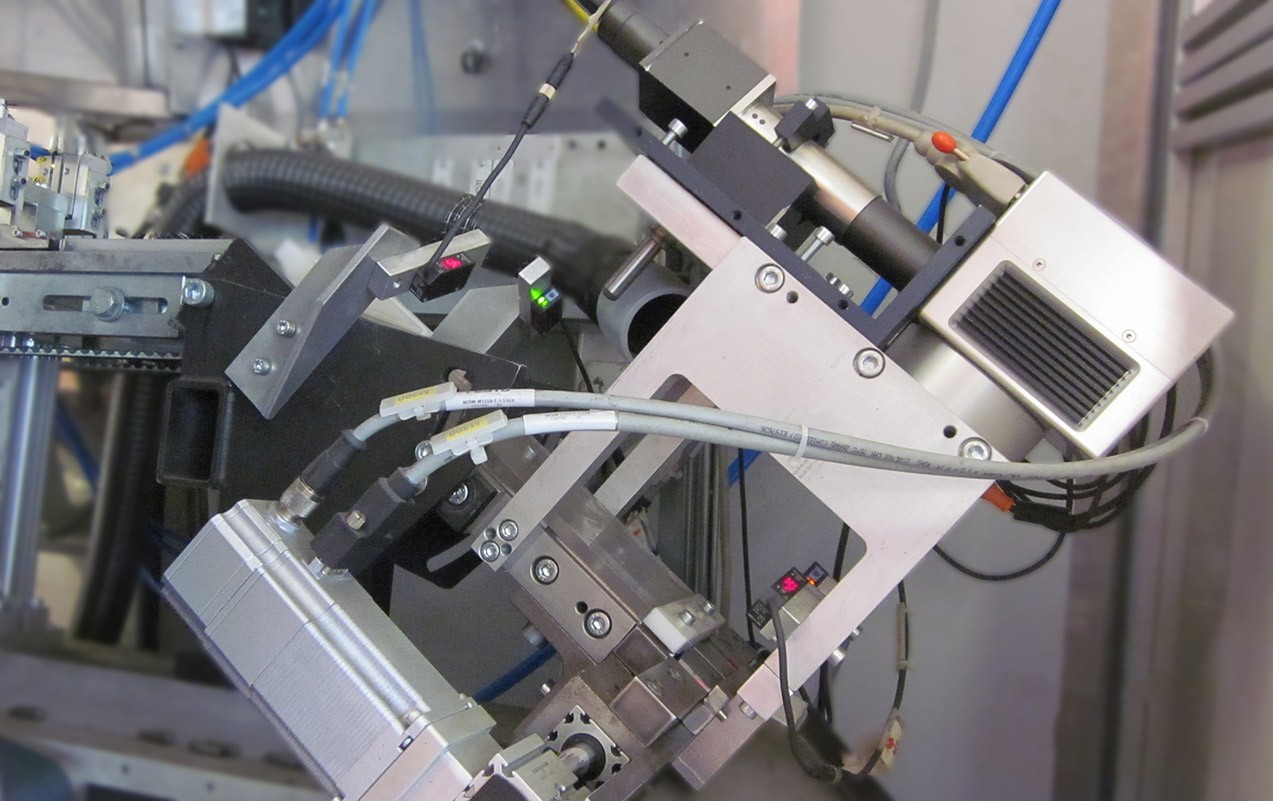

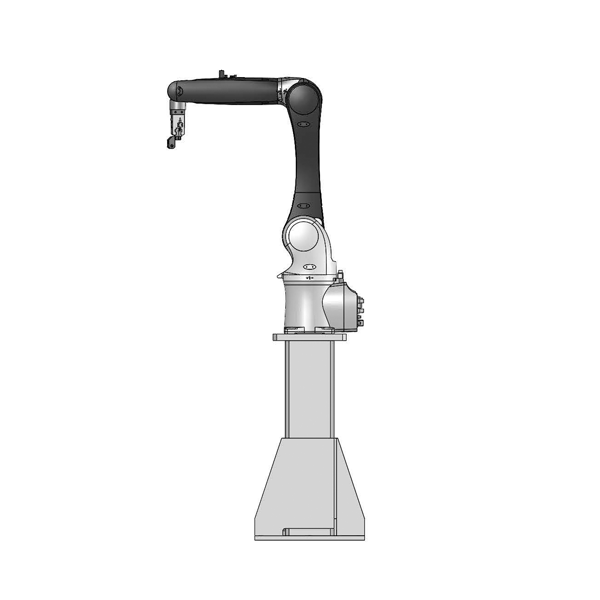

Robot applications

Information

Robot technology offers our customers flexible solutions for the systematic feed and separation of parts in the feeding process. It enables the targeted input of bulk material and positioning of parts.

Example of use

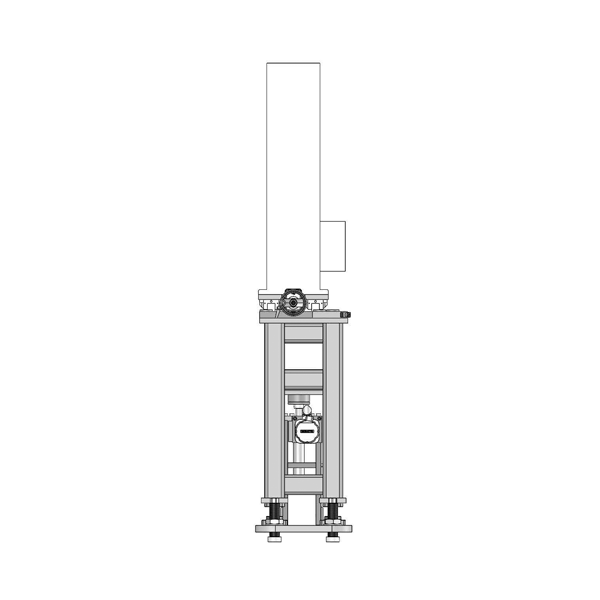

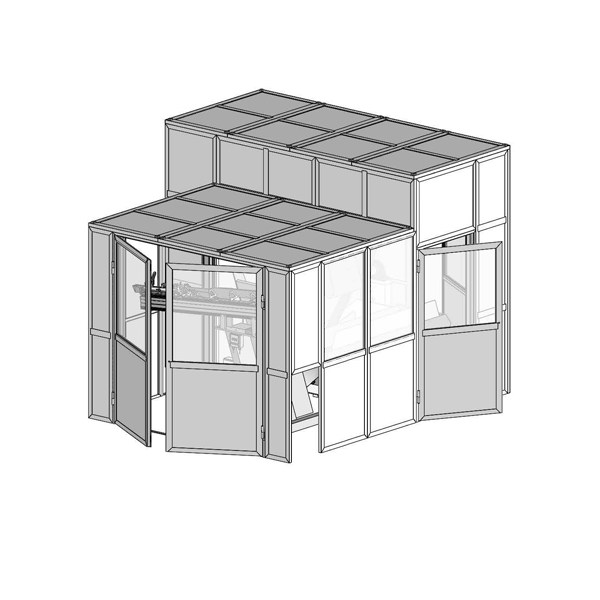

Noise-insulating hoods & safety enclosures

Information

A safety enclosure surrounds the working area, preventing people from accessing or entering the working area of the machine. The working area of the entire machine or individual working areas or machine components can be enclosed. A noise-insulating hood reduces the noise level.

Example of use