Feeding technology for the plastics industry

The variety of parts in the plastics industry is almost limitless – all types of injection molded parts, washers, tubes… the list goes on. High output, fault-free operation and an efficient overall concept are essential. You can trust in our expertise: we know the requirements and fit entire assembly lines with reliable feeding technology.

The challenges

Mass production in the plastics technology sector requires extremely high capacity and careful handling of what can be very sensitive feed parts. The noise of the production process is also an important consideration. As plastic parts can have a wide range of properties from elastic to plastic or coated, the materials used must be exactly tailored to the products.

Our expertise

Our extensive experience in feeding for bulk plastic parts means we can draw on a wealth of parts and solutions. This enables us to implement ideal feeding solution for almost every part. Our plants are often part of the direct interface to injection molding machines and their robustness makes them a perfect option for fault-free and continuous use in difficult conditions.

Below is just a selection of parts for which we have already designed and produced feed devices.

Sealing elements

25x35x45 mm

Information

Sorting parts: Sealing elements

Our solution:

Single-lane feeding device with a vibrating conveyor, conveyor belt, sorting track and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

18 parts per minute

Application video

Roller cages

40x15x15 mm

Information

Sorting parts: Roller cages

Our solution:

Single-lane feeding device with a storage conveyor, cleat conveyor and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

55 parts per minute

Application video

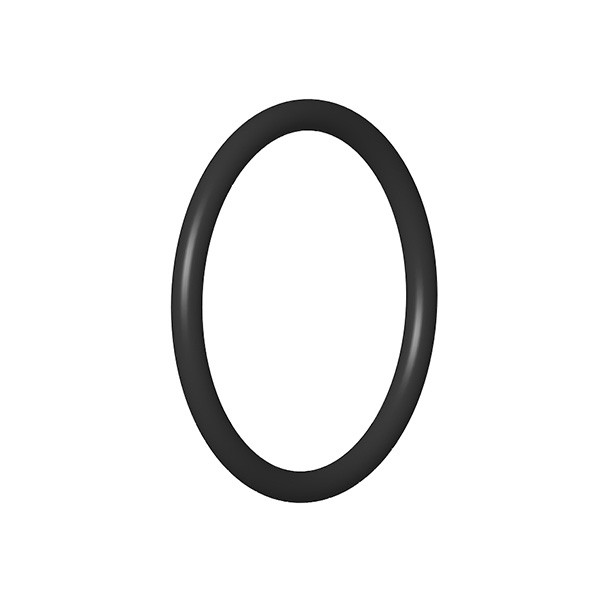

O-rings

2x22x22 mm

Information

Sorting parts: O-rings

Our solution:

Single-lane feeding device with a drum conveyor, sorting track and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

10 parts per minute

Application video

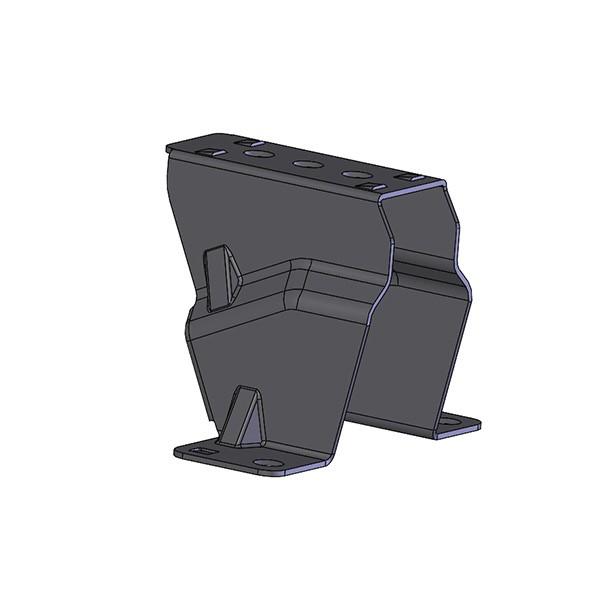

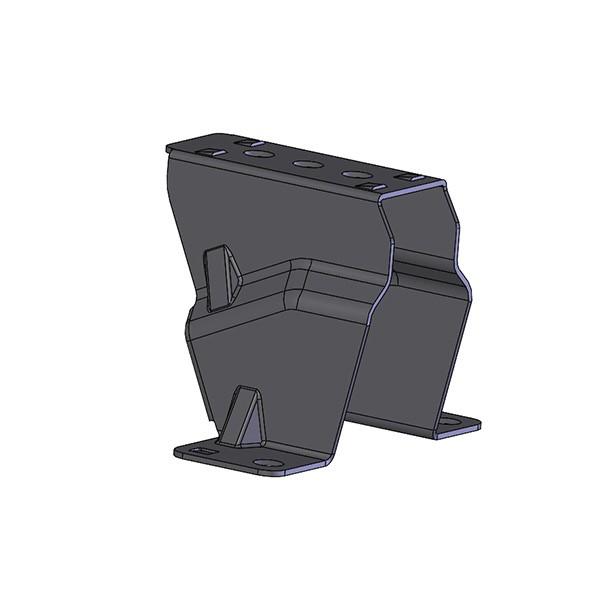

Consoles

70x70x100 mm

Information

Sorting parts: Consoles

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

10 parts per minute

Application video

Below is just a selection of parts for which we have already designed and produced feed devices.

Sealing elements

25x35x45 mm

Information

Sorting parts: Sealing elements

Our solution:

Single-lane feeding device with a vibrating conveyor, conveyor belt, sorting track and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

18 parts per minute

Application video

Consoles

70x70x100 mm

Information

Sorting parts: Consoles

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

10 parts per minute

Application video

Roller cages

40x15x15 mm

Information

Sorting parts: Roller cages

Our solution:

Single-lane feeding device with a storage conveyor, cleat conveyor and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

55 parts per minute

Application video

O-rings

2x22x22 mm

Information

Sorting parts: O-rings

Our solution:

Single-lane feeding device with a drum conveyor, sorting track and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

10 parts per minute