Stepfeeders

Köberlein & Seigert supplies custom feed devices. For parts feeding with our feed systems, our portfolio includes tried and tested stepfeeders with excellent product features.

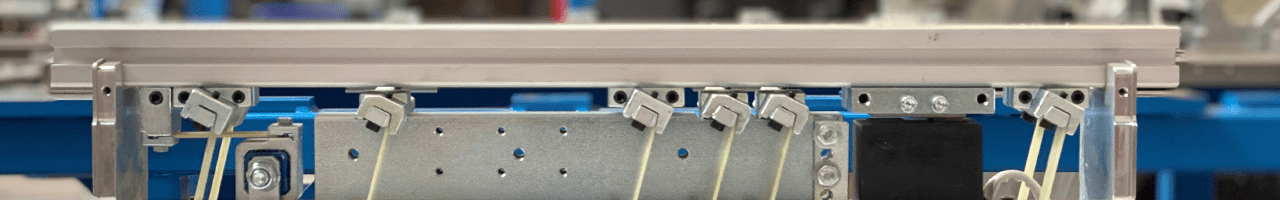

The material to be sorted is removed from the hopper and transferred to the downstream component with the help of opposing pushers. Our stepfeeder technology is tailored to gentle handling – and the design also guarantees low-noise operation. We optimize the likely positions and quantities by adapting our stepfeeders to the specific material. Köberlein & Seigert stepfeeders vary in size and design and are adapted to your capacity and part geometry requirements.

Advantages of our product

- Low-vibration provisioning

- Pusher width up to 1000 mm

- Transfer height up to 3000 mm

- Conveyor speed up to 10 meters per minute

- Low, ergonomic input heights even with high outlet heights

- Variable pusher thickness and width

- Low-wear pushers

- Electromechanical drive

- Very quiet operation

- Much quieter than vibrating bowls

- Opposing pusher system

- Few conveyor steps needed

- Compact design

- Individually adjustable height

Our models/series

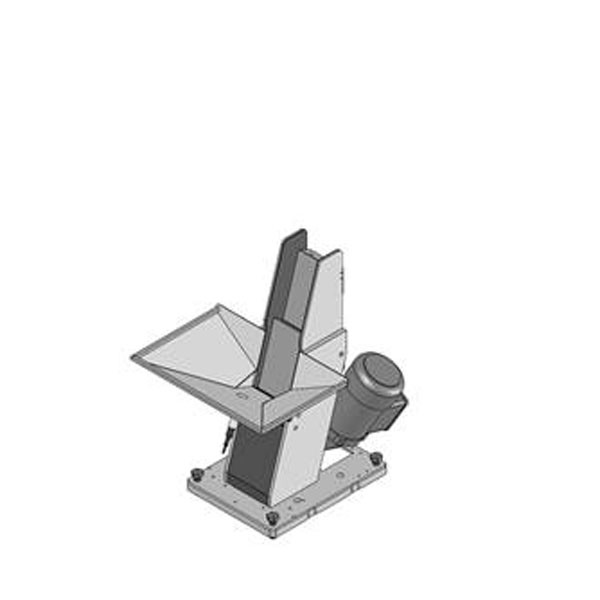

C series

Information

This tabletop device is perfect for small parts. Highly adjustable, it is the ideal solution for presorting and positioning parts for transfer. C-series stepfeeders are an all-purpose solution for parts provisioning and linear conveying with Köberlein & Seigert feed products. They are also extremely low-maintenance.

Transfer height: approx. 530 mm

Drive: electric / pneumatic

Examples of feed parts:

- Formed parts up to 50 mm long, 15 mm wide, and 15 mm high

- Electrical contacts

- Small parts

- Screws from M2 to M10, 5 mm to 49 mm long

- Washers from Ø2 to Ø12 mm and nuts from M2 to M12

- Pins and sleeves from Ø2 to Ø12 mm and up to c. 50 mm long

Feed part material: Metal, plastic, glass, ceramic, wood, composites and coated materials

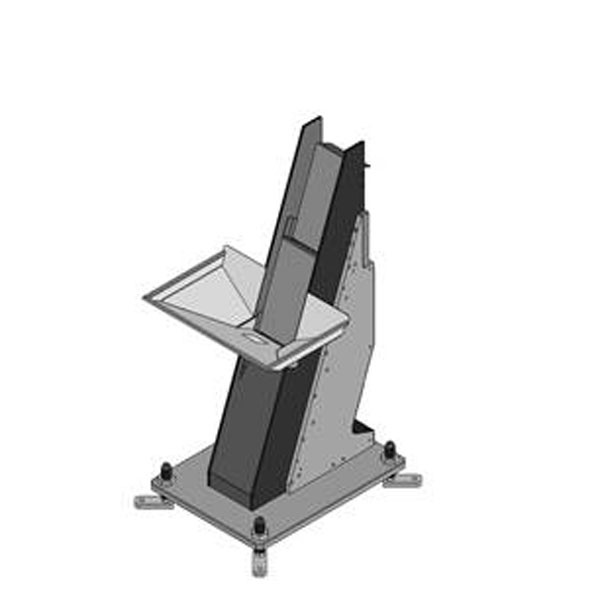

M/S series

Information

M/S-series stepfeeders are particularly suited to medium-sized feed parts and their transfer height and width can be adapted to customer requirements. These devices are compact and ensure very gentle handling of the material to be sorted. The design makes for a highly ergonomic input height. M/S-series stepfeeders can be expanded as required with Köberlein & Seigert feeding technology products.

Transfer height: 660 to approx. 1400 mm

Drive: electric

Examples of feed parts:

- Formed parts up to 150 mm long, 50 mm wide, and 25 mm high

- Furniture hinges

- Key blanks

- Sheet metal parts up to roughly hand-size

- Compact motor and chassis components

- Screws from M2 to M30, 2.5 mm to 300 mm long

- Washers and nuts from M2 to M36

- Washers up to Ø150 mm

- Pins and sleeves from Ø1.5 to Ø100 mm and up to approx. 300 mm long

Feed part material: Metal, plastic, glass, ceramic, wood, composites and coated materials

SP series

Information

The SP-series stepfeeders operate with a pneumatic drive. These stepfeeders are a great, cost-effective alternative for small quantities or lower throughput. The tried and tested pusher system design ensures gentle transfer of the material to be sorted. SP-series stepfeeders are also very low-maintenance.

Transfer height: approx. 1000 mm

Drive: pneumatic

Examples of feed parts:

- Formed parts up to 50 mm long, 25 mm wide, and 15 mm high

- Screws from M2 to M10, 2.5 mm to 50 mm long

- Washers and nuts from M2 to M12

- Pins and sleeves from Ø2 to Ø12 mm and up to approx. 50 mm long

Feed part material: Metal, plastic, glass, ceramic, wood, composites and coated materials

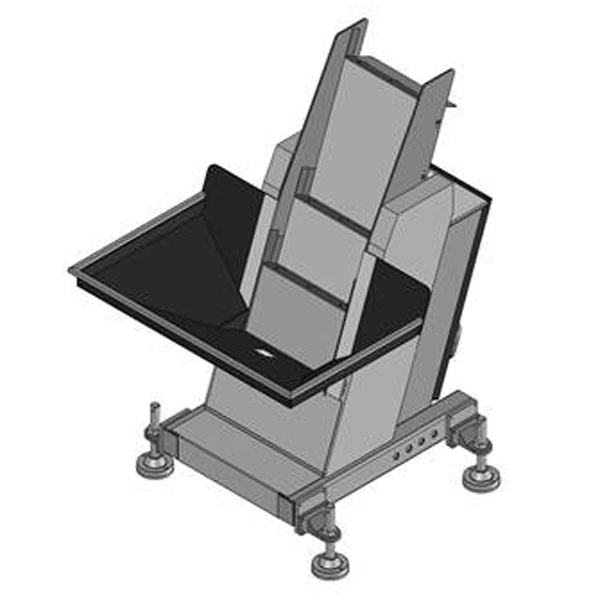

A series

Information

Sturdy in design, A-series stepfeeders are perfect for large feed parts – and still move parts rapidly and quietly. These stepfeeders can easily deal with the presorting and transfer of large feed parts (such as sheet metal parts), compact and heavy cast and turned parts, and bulk material part weights of up to 7 kilograms.

Ergonomic filling heights with transfer heights of up to 3 meters are also possible with A-series stepfeeders. Another key benefit is the variable width and thickness of the pushers, which allows specific adjustments in line with customer requirements.

Transfer height: 1050 to approx. 3000 mm

Drive: electric

Examples of feed parts:

- Formed parts up to 400 mm long, 150 mm wide, and 100 mm high

- Small and large feed parts (e.g. sheet metal parts)

- Compact and heavy cast and turned parts

- Compact motor and chassis components

- Bulk material with part weights of up to 7 kilograms

- Screws from M4 to M30, 5 mm to 500 mm long

- Washers and nuts from M4 to M36

- Pins and sleeves from Ø4 to Ø100 mm and up to approx. 300 mm long

Feed part material: Metal, plastic, glass, ceramic, wood, composites and coated materials