Feeding technology | Integrated feeding solutions | Interlinking and assembly automation

Feeding technology

Our core business is feeding devices for bulk parts in industrial production. At the heart of our solutions is our tried and tested stepfeeder technology.

Stepfeeders offer much greater throughput, a much longer service life and much more sensitive product transport than other feed technologies.

Stepfeeders also help compliance with ever-stricter health and safety requirements as they are much quieter than bowl feeders.

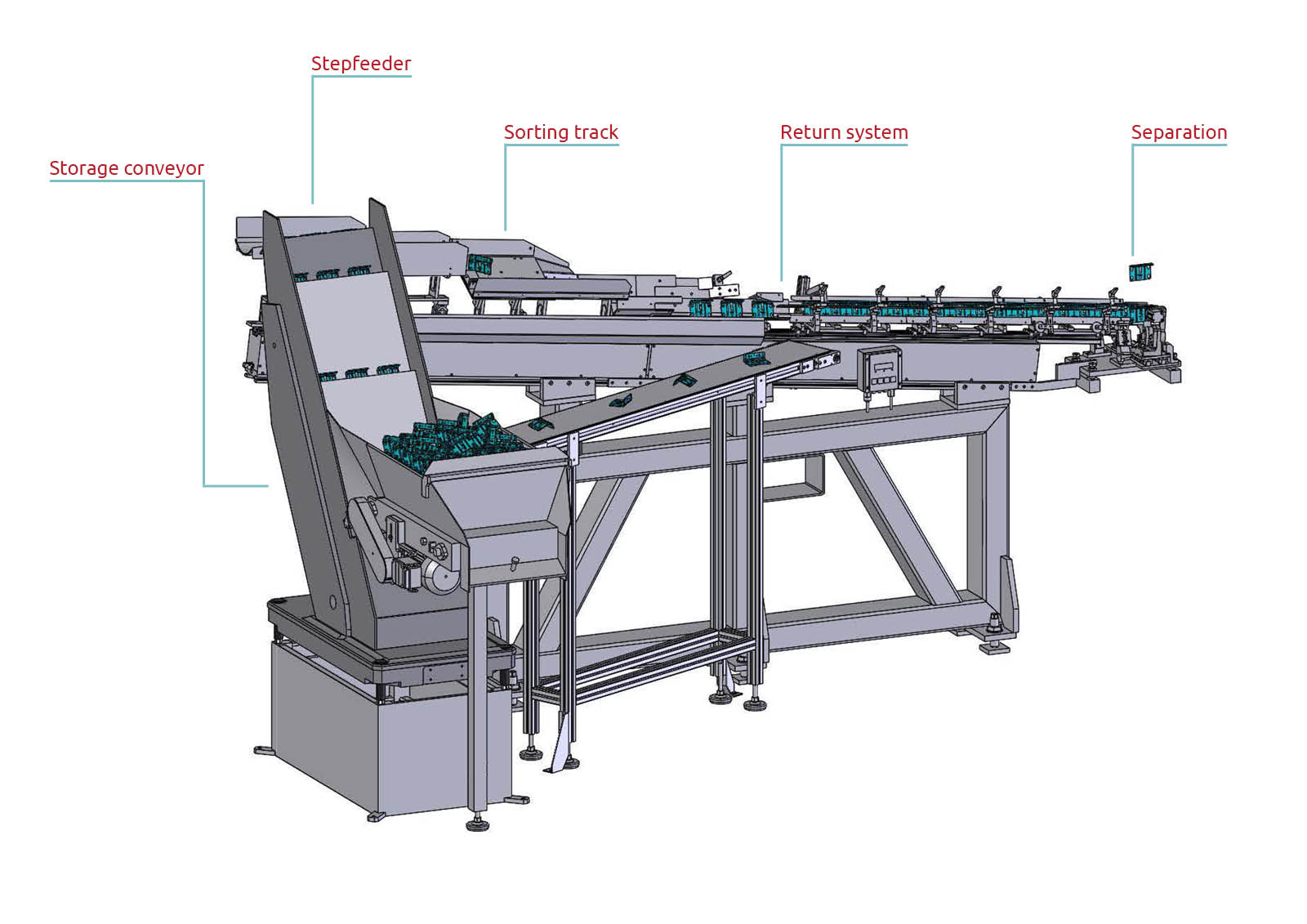

Material flow

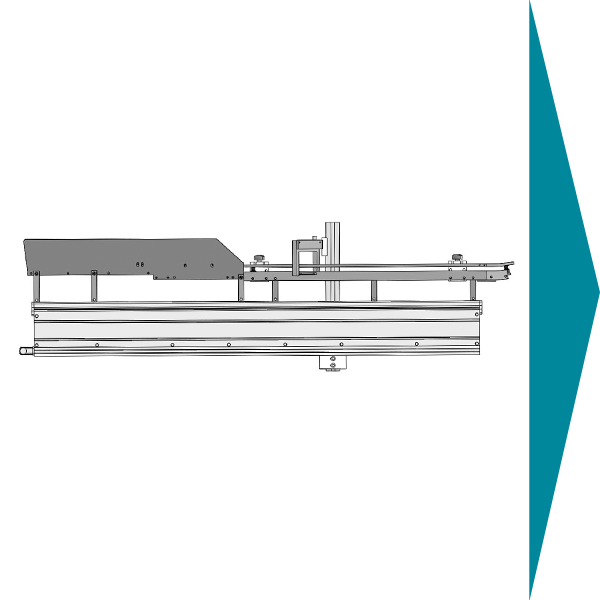

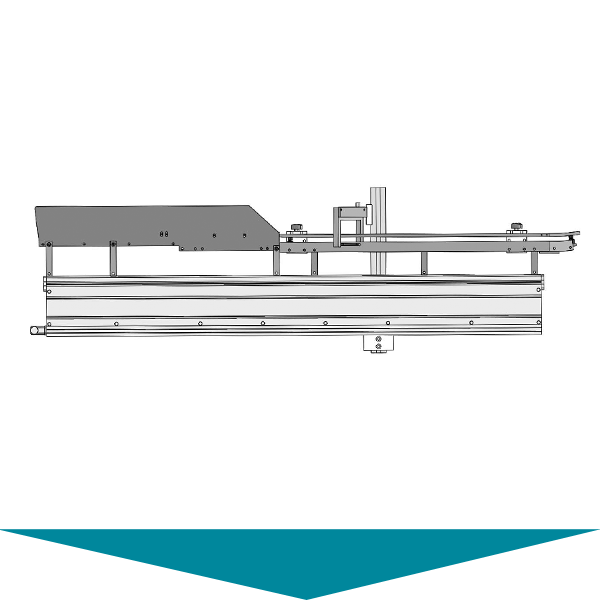

Storage conveyor

The storage conveyor or vibrating conveyor stores the material to be sorted, separates geometrically complex parts and transfers them to the stepfeeder.

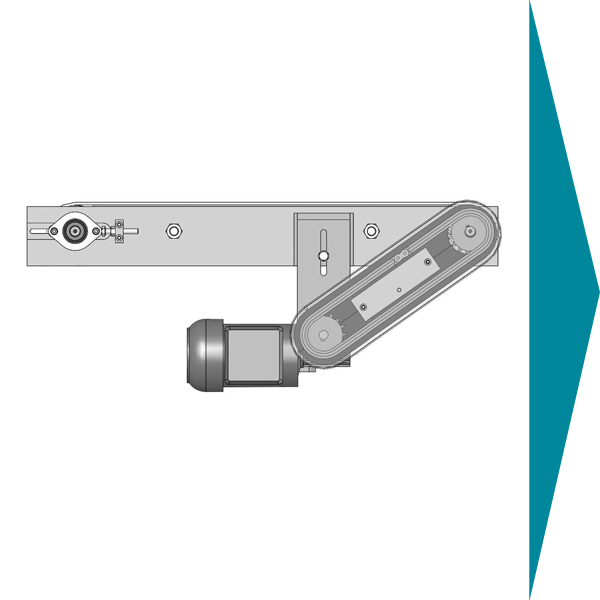

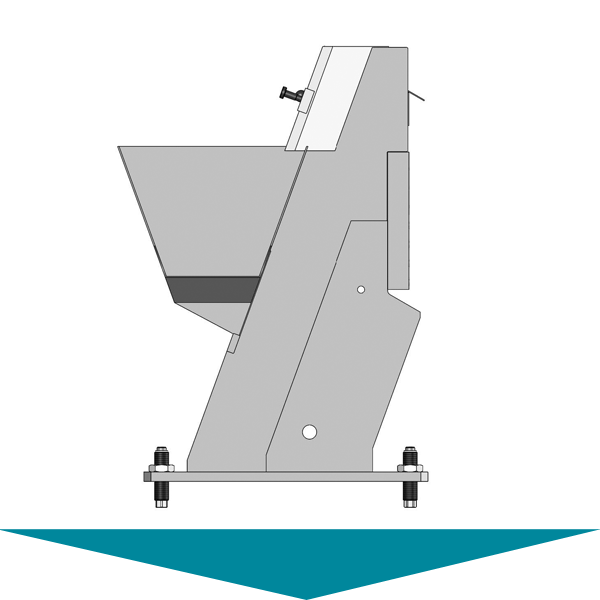

Stepfeeder

The stepfeeder transports the material to be sorted gently and quietly to the sorting track.

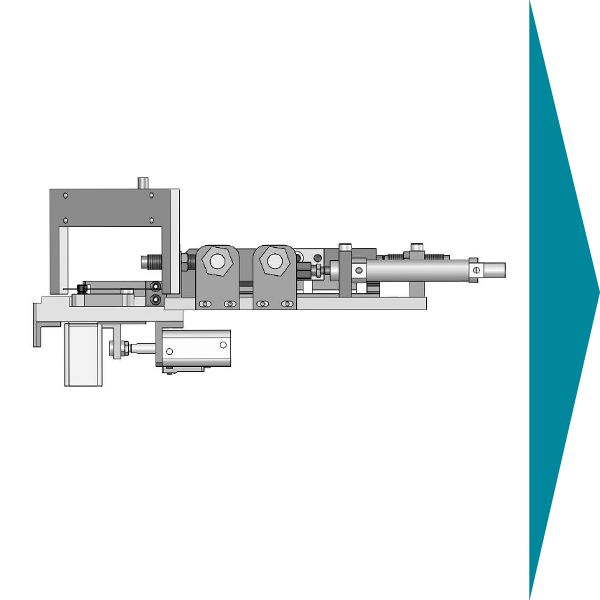

Sorting track

The sorting track puts the material to be sorted in the correct position. Incorrectly positioned parts are rejected.

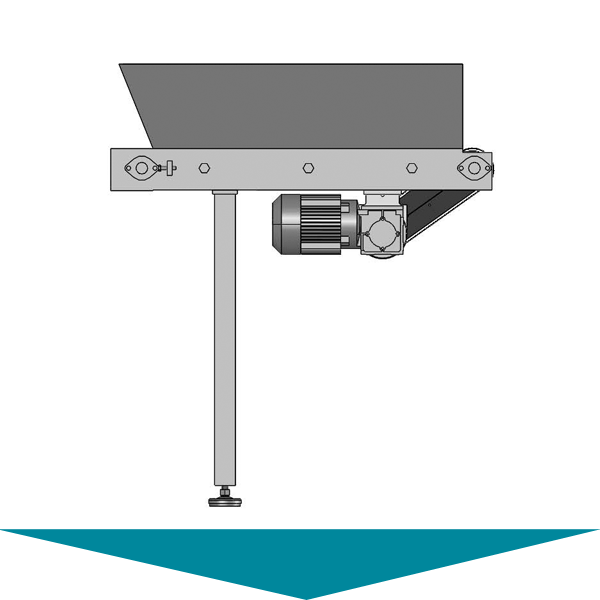

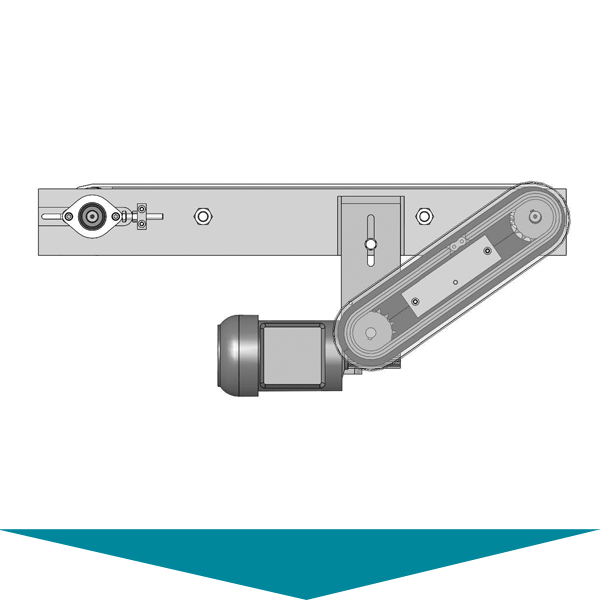

Return system

If the material is in the wrong position, it is automatically returned to the conveying process by the return system.

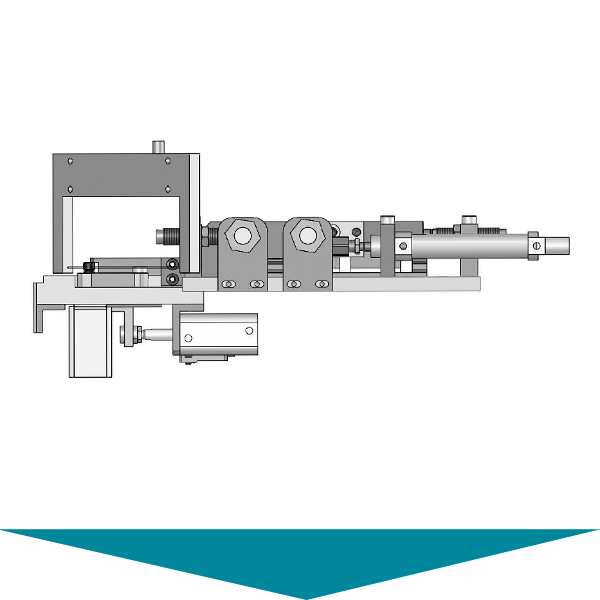

Separation

Separation transfers the material correctly to the downstream production step.

Material flow

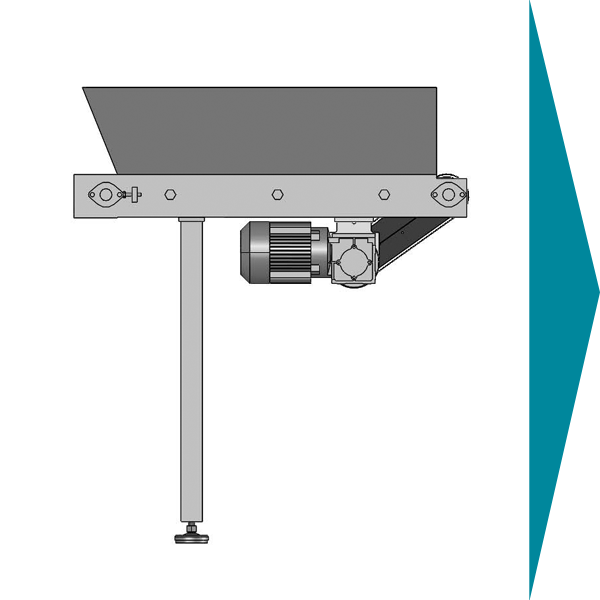

Storage conveyor

The storage conveyor or vibrating conveyor stores the material to be sorted, separates geometrically complex parts and transfers them to the stepfeeder.

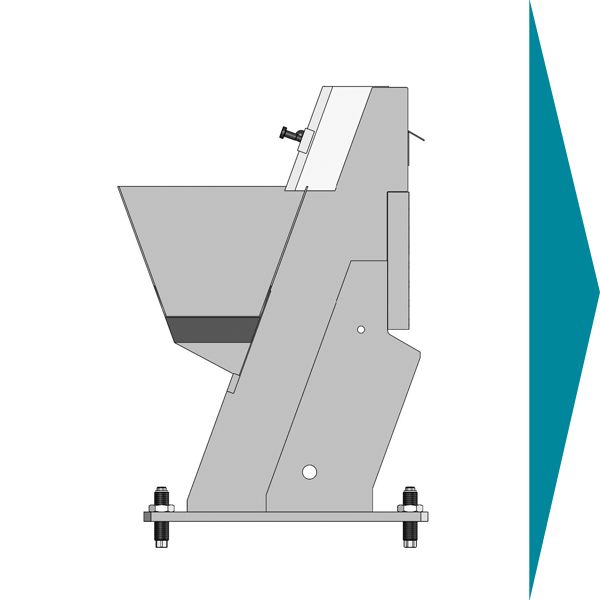

Stepfeeder

The stepfeeder transports the material to be sorted gently and quietly to the sorting track.

Sorting track

The sorting track puts the material to be sorted in the correct position. Incorrectly positioned parts are rejected.

Return system

If the material is in the wrong position, it is automatically returned to the conveying process by the return system.

Separation

Separation transfers the material correctly to the downstream production step.