Feeding technology for the electrical industry

Our long-standing partners in the electrical industry use our feeding technology for electrical contacts, switches, support plates and housing, to name just a small selection. High throughput and, of course, low-maintenance and reliable continuous operation are central to mass production. We can draw on our extensive experience to develop the right, efficient feed device for your product too.

The challenges

Mass production in the electrical industry requires both high capacity and careful handling of what can be very sensitive feed parts. Dimensions range from the smallest of contacts to switch elements and housing. Durability and a long service life are essential if a production plant is to be operated efficiently throughout its life cycle.

Our expertise

Our plants for the electrical industry often run in continuous operation for several years and have very low maintenance costs. The benefits of our robust, advanced technology are particularly striking in intensive use.

Below is just a selection of parts for which we have already designed and produced feed devices.

Contact elements with M4 screws

40x10x25 mm

Information

Sorting parts: Contact elements with M4 screws

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

55 parts per minute

Application video

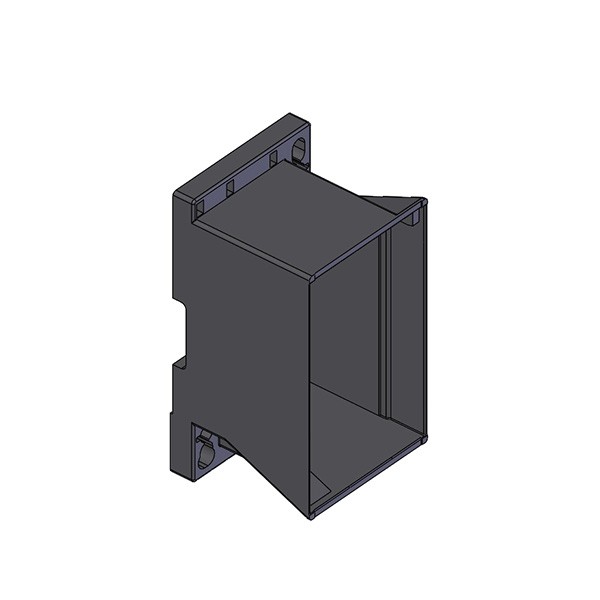

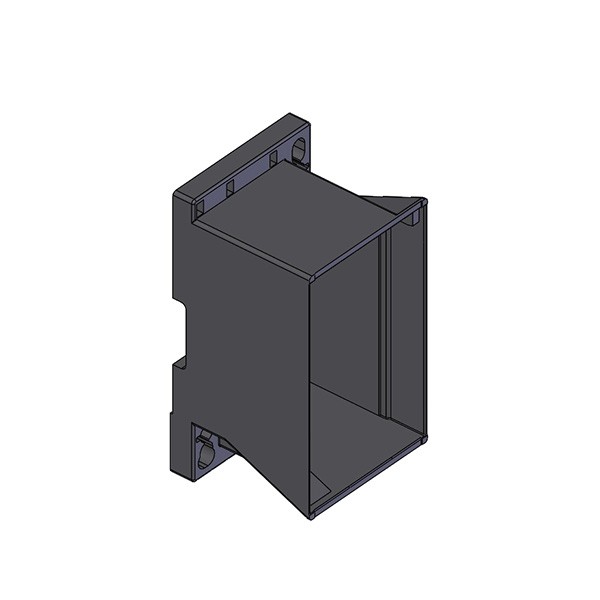

Housing

25x45x100 mm

Information

Sorting parts: Housing

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

6 parts per minute

Application video

Magnet chambers

45x45x85 mm

Information

Sorting parts: Magnet chambers

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track with conveyor belt for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

25 parts per minute

Application video

Magnet chambers

40x10x15 mm

Information

Sorting parts: Schaltstücke Schließer

Our solution:

Triple-lane solution comprising three parallel feeding devices, each with a vibrating conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

40 parts per minute

Application video

Below is just a selection of parts for which we have already designed and produced feed devices.

Contact elements with M4 screws

40x10x25 mm

Information

Sorting parts: Contact elements with M4 screws

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

55 parts per minute

Application video

Magnet chambers

40x10x15 mm

Information

Sorting parts: Schaltstücke Schließer

Our solution:

Triple-lane solution comprising three parallel feeding devices, each with a vibrating conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

40 parts per minute

Application video

Housing

25x45x100 mm

Information

Sorting parts: Housing

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

6 parts per minute

Application video

Magnet chambers

45x45x85 mm

Information

Sorting parts: Magnet chambers

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track with conveyor belt for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

25 parts per minute