Palletizing systems

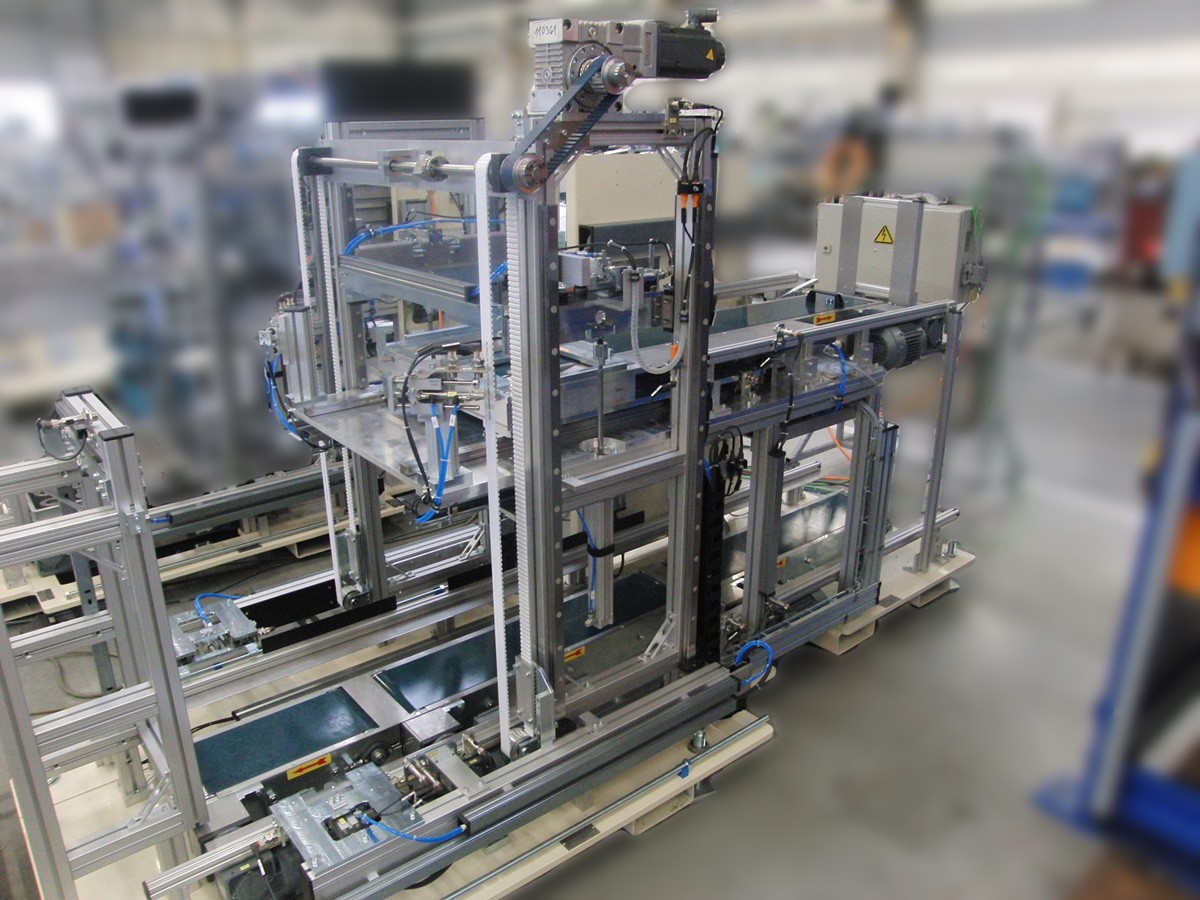

Köberlein & Seigert offers custom solutions for moving standardized containers in the production process. There is increasing demand for gentle on-site feed part transport in containers. Custom palletizing systems from Köberlein & Seigert meet this need. With individually tailored belt lengths and container sizes, Köberlein & Seigert palletizers can be easily integrated into almost every production process.

The basic principle of the palletizing systems is stacking containers on a conveyor belt (or roller conveyor) in readiness. A conveyor belt then feeds the stack of containers into a lifting unit, which sends individual containers for loading and unloading. After this process, the containers are stacked again and moved onto a separate conveyor belt.

Advantages of our product

- Gentle feed and removal

- Variable container size

- Variable belt length (variable capacity requirements)

- Integration into almost any production process