Feeding technology for the furniture industry

Manufacturers of hinges and window fittings have been using our feeding technology for years. Stepfeeder technology makes it possible to feed even complex parts such as hinges – from standard to custom designs – at high speed. We are also able to feed long parts such as those used in window systems into the assembly process, reliably and in the correct position.

The challenges

The main priorities in furniture production are high feed device capacity and fault-free and continuous operation. Parts are frequently complex, and this requires advanced sorting track construction and handling.

Our expertise

We have decades of experience in the field of automated feeding for furniture and window fittings and are very familiar with the specific requirements of our customers. High plant availability and secure and correct transfer to the production process are the basis for efficient plant operation. To achieve the high throughout needed, we often use multi-lane feed systems that can offer capacities of well over 100 parts per minute.

Below is just a selection of parts for which we have already designed and produced feed devices.

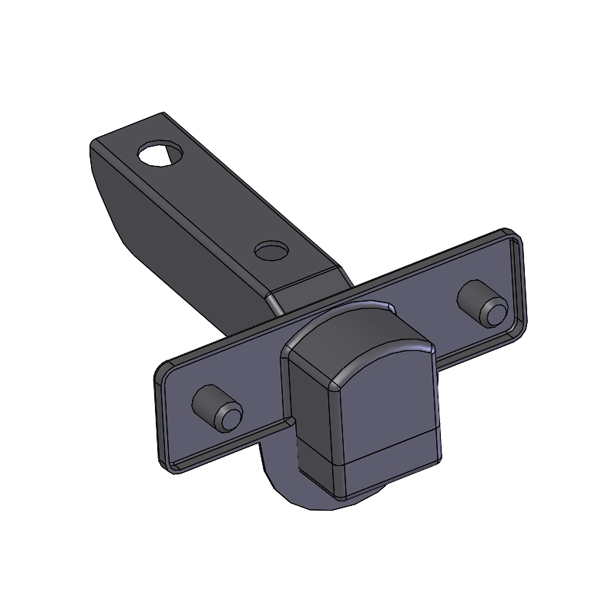

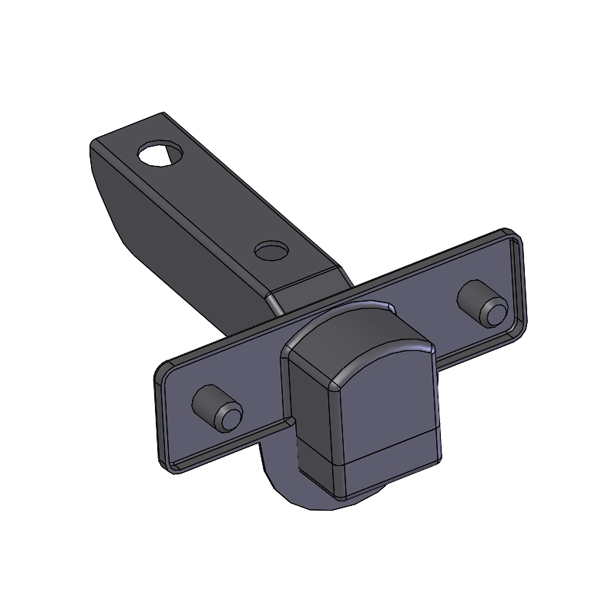

Hinges

80x70x35 mm

Information

Sorting parts: Hinges

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

40 parts per minute

Application video

Torsion springs

ø=4×10 mm

Information

Sorting parts: Torsion springs

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

45 parts per minute

Application video

Key blanks

30x4x11 mm

Information

Sorting parts: Key blanks

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

25 parts per minute

Application video

Sheet metal parts

5x15x40 mm

Information

Sorting parts: Sheet metal parts

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

45 parts per minute

Application video

Below is just a selection of parts for which we have already designed and produced feed devices.

Hinges

80x70x35 mm

Information

Sorting parts: Hinges

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

40 parts per minute

Application video

Sheet metal parts

5x15x40 mm

Information

Sorting parts: Sheet metal parts

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

45 parts per minute

Application video

Torsion springs

ø=4×10 mm

Information

Sorting parts: Torsion springs

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

45 parts per minute

Application video

Key blanks

30x4x11 mm

Information

Sorting parts: Key blanks

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

25 parts per minute