Feeding technology for the automotive industry

Valve locks or valve springs in motor construction, screws or sheet metal parts in body construction, or contacts in battery assembly… Our feeding technology ensures the efficient and precise supply of series components to the robot or assembly line.

The challenges

The automotive industry has high requirements for availability and safety, as well as smooth and continuous plant operation. Automation solutions must also work efficiently throughout their entire life cycle.

Our expertise

We have decades of experience in the automotive industry and are very familiar with the requirements and specifications of our customers. We comply with safety and industry standards, and the high availability and robustness of our lines enables efficient process optimization in the production process.

Body construction

Below is just a selection of parts for which we have already designed and produced feed devices.

Foam models

150x85x30 mm

Information

Sorting parts: Foam models

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

2 parts per minute

Application video

Fastening clips

15x35x45 mm

Information

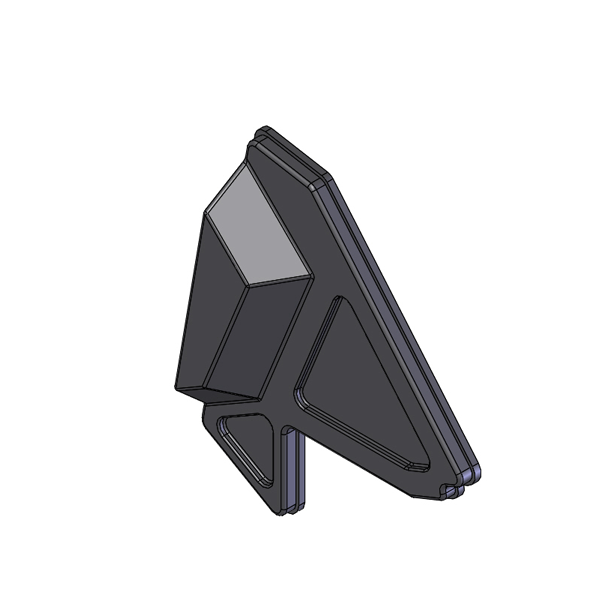

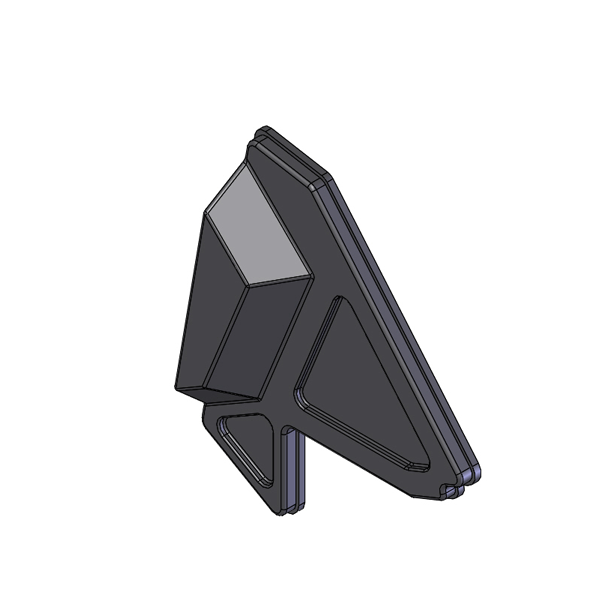

Sorting parts: Fastening clips

Our solution:

Single-lane feeding device with a vibrating conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

5 parts every 97 seconds

Application video

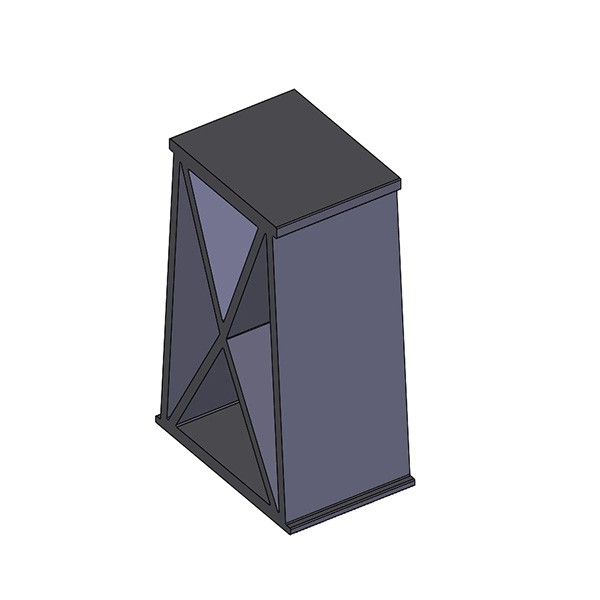

Body parts

200x130x90 mm

Information

Sorting parts: Body parts

Our solution:

Feeding device with manual placement, from which a single-lane sorting track feeds the parts into the separation process. Separation correctly transfers the parts to the downstream production step.

Performance:

1 part per minute

Application video

Fasteners

Washer ø=20 mm; H=10 mm

Information

Sorting parts: Fasteners

Our solution:

Single-lane feeding device with a stepfeeder, sorting track and separation. Integrated fan blower technology correctly transfers the parts in a catching station to the downstream production step.

Performance:

8 parts every 117 seconds

Application video

Body construction

Below is just a selection of parts for which we have already designed and produced feed devices.

Foam models

150x85x30 mm

Information

Sorting parts: Foam models

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

2 parts per minute

Application video

Fasteners

Washer ø=20 mm; H=10 mm

Information

Sorting parts: Fasteners

Our solution:

Single-lane feeding device with a stepfeeder, sorting track and separation. Integrated fan blower technology correctly transfers the parts in a catching station to the downstream production step.

Performance:

8 parts every 117 seconds

Application video

Fastening clips

15x35x45 mm

Information

Sorting parts: Fastening clips

Our solution:

Single-lane feeding device with a vibrating conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

5 parts every 97 seconds

Application video

Body parts

200x130x90 mm

Information

Sorting parts: Body parts

Our solution:

Feeding device with manual placement, from which a single-lane sorting track feeds the parts into the separation process. Separation correctly transfers the parts to the downstream production step.

Performance:

1 part per minute

Application video

E-mobility

Below is just a selection of parts for which we have already designed and produced feed devices.

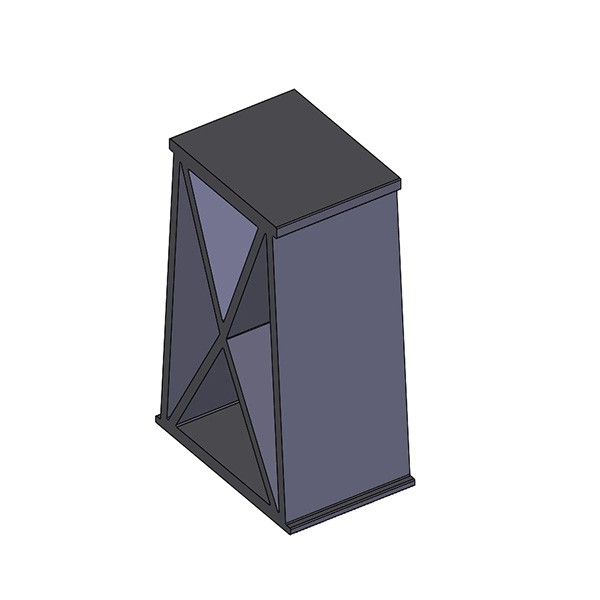

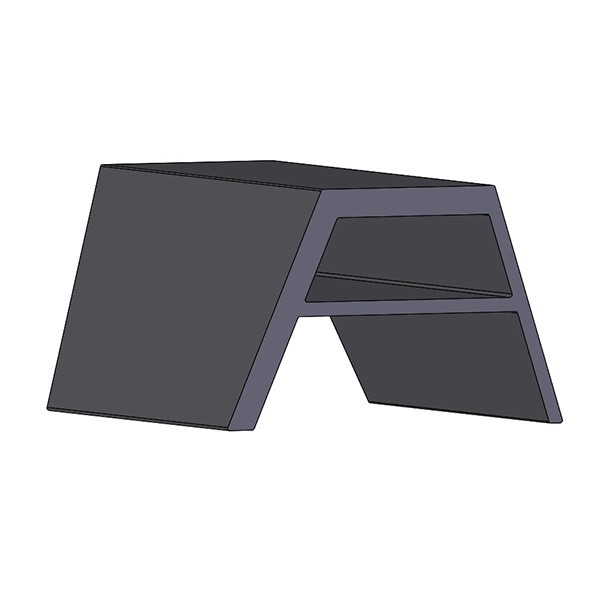

Aluminum profile parts

130×70/90×50 mm

Information

Sorting parts: Aluminum profile parts

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

4 parts every 80 seconds

Application video

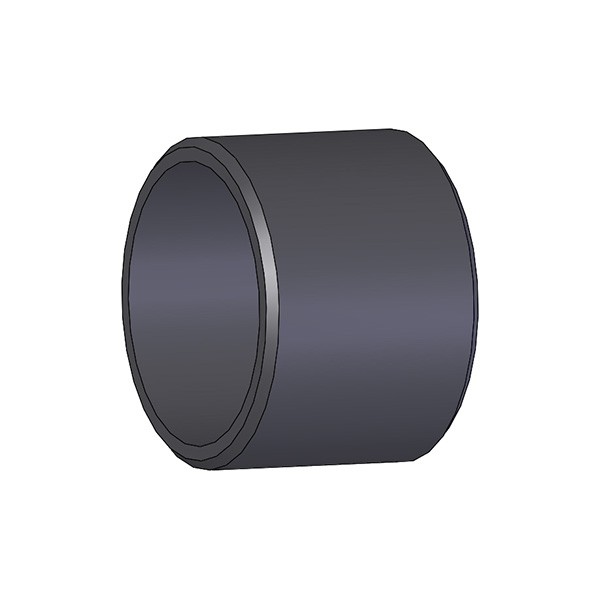

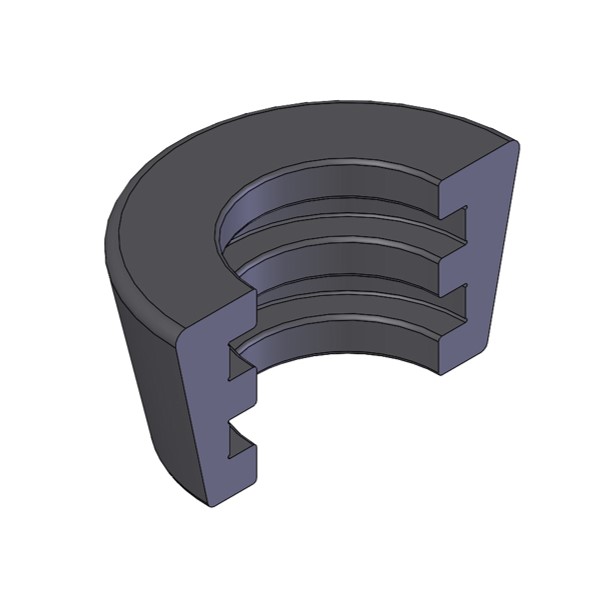

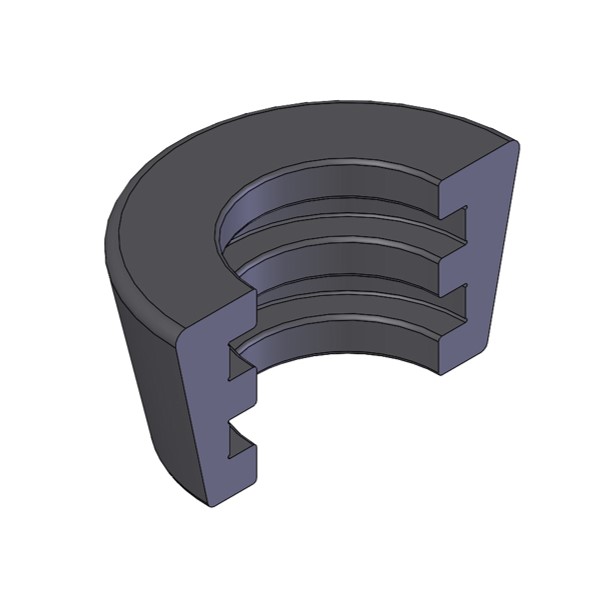

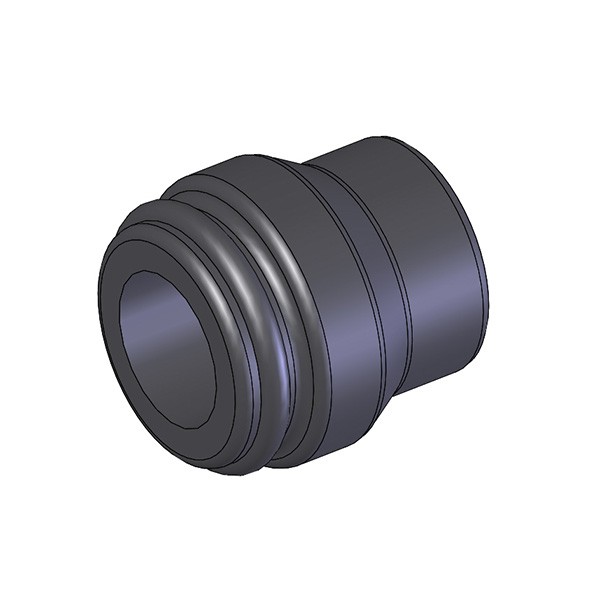

Sleeves (short)

External ø=40 mm; H=20 mm

Information

Sorting parts: Sleeves (short)

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

2 parts per minute

Application video

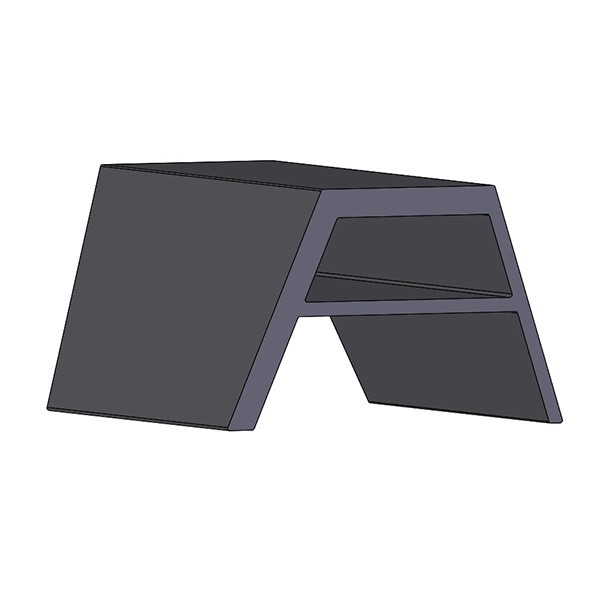

Consoles

50x80x80 mm

Information

Sorting parts: Consoles

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

1 part every 120 seconds

Application video

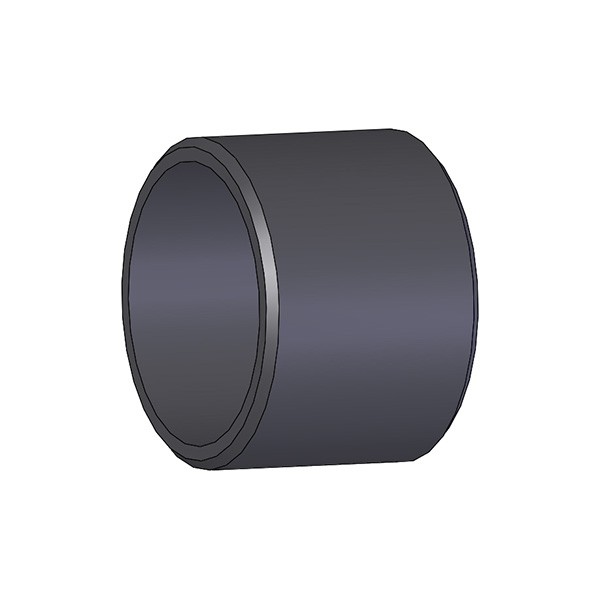

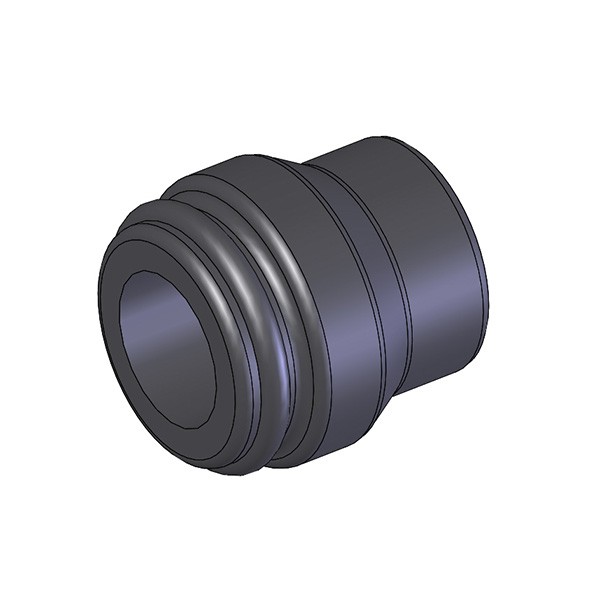

Sleeves (long)

External ø=30 mm; H=45 mm

Information

Sorting parts: Sleeves (long)

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

7 parts per minute

Application video

E-mobility

Below is just a selection of parts for which we have already designed and produced feed devices.

Aluminum profile parts

130×70/90×50 mm

Information

Sorting parts: Aluminum profile parts

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

4 parts every 80 seconds

Application video

Sleeves (long)

External ø=30 mm; H=45 mm

Information

Sorting parts: Sleeves (long)

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

7 parts per minute

Application video

Sleeves (short)

External ø=40 mm; H=20 mm

Information

Sorting parts: Sleeves (short)

Our solution:

Single-lane feeding device with a stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

2 parts per minute

Application video

Consoles

50x80x80 mm

Information

Sorting parts: Consoles

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

1 part every 120 seconds

Application video

Motor assembly

Below is just a selection of parts for which we have already designed and produced feed devices.

Valve locks

Ø=10 mm; L=5 mm

Information

Sorting parts: Valve locks

Our solution:

Four-lane feeding device with a stepfeeder, sorting track and separation. Integrated 8-hose fan blower correctly transfers the parts to the downstream production step.

Performance:

64 parts per minute

Application video

Valve stem seals

External Ø=12 mm; H=10 mm

Information

Sorting parts: Valve stem seals

Our solution:

Single-lane feeding device with a stepfeeder, sorting track with integrated incorrect part ejection for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

16 parts per minute

Application video

Valve fit rings

External Ø=30 mm; H=5 mm

Information

Sorting parts: Valve fit ring

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

300 parts per minute

Application video

Valve springs

External ø=20 mm; Internal ø=15 mm; L=50 mm

Information

Sorting parts: Valve springs

Our solution:

Double-lane solution comprising two parallel feeding devices, each with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

32 parts per minute

Application video

Motor assembly

Below is just a selection of parts for which we have already designed and produced feed devices.

Valve locks

Ø=10 mm; L=5 mm

Information

Sorting parts: Valve locks

Our solution:

Four-lane feeding device with a stepfeeder, sorting track and separation. Integrated 8-hose fan blower correctly transfers the parts to the downstream production step.

Performance:

64 parts per minute

Application video

Valve springs

External ø=20 mm; Internal ø=15 mm; L=50 mm

Information

Sorting parts: Valve springs

Our solution:

Double-lane solution comprising two parallel feeding devices, each with a storage conveyor, stepfeeder and sorting track for positioning and separation for correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

32 parts per minute

Application video

Valve stem seals

External Ø=12 mm; H=10 mm

Information

Sorting parts: Valve stem seals

Our solution:

Single-lane feeding device with a stepfeeder, sorting track with integrated incorrect part ejection for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

16 parts per minute

Application video

Valve fit rings

External Ø=30 mm; H=5 mm

Information

Sorting parts: Valve fit ring

Our solution:

Single-lane feeding device with a storage conveyor, stepfeeder and sorting track for positioning and correct transfer to the downstream production step. Incorrectly positioned parts are automatically returned to the conveying process.

Performance:

300 parts per minute